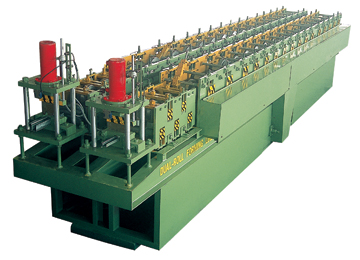

Metal Stud Track Roll Forming Machine

Dimension(L*W*H): 5*1.0*1.3M

Weight: 3500 kg

Warranty: 1 Year

Key Selling Points: Easy to Operate

Rolling thinckness: 0.3-0.8mm

Product Introduction

Metal stud track roll forming machine is specially designed for the production of metal stud track - a framework for walls, ceilings and floors in commercial and residential buildings. Its rolling thickness is 0.3-0.8mm, so it is capable of producing metal stud rails of different thicknesses suitable for various industries. This machine is relatively easy to use thanks to its user-friendly touch screen control panel as well as PLC system. The operator simply loads the metal coil onto the machine, adjusts the machine settings for the desired size and shape, and turns the machine on to begin automatic production. Therefore, this machine is an ideal solution for customers who are looking for customers who want to simplify the production process and increase productivity. In addition, we can customize the voltage level of the machine for you, or customize the capacity according to your business scale. Each machine has a one-year warranty period, and we have professional technicians to provide guidance for installation and maintenance.

Benefits

1. Save time and cost: Equipped with high-power motors and components from famous brands such as Siemens, this machine can achieve a production capacity of 10-15m/min, which can save users a lot of time and cost.

2. Consistent Quality: Thanks to its hydraulic cutting system that ensures precise, clean cuts every time, this machine can produce metal stud rails that are uniform in size and shape.

3. Low maintenance: Thanks to high-performance electrical components and modular structural design, this metal stud track roll forming machine will not break down easily and is very easy to maintain and repair when it breaks down.

4. Speed up efficiency: This machine has a user-friendly touch screen control panel, so operators can easily adjust machine settings, which effectively speeds up production efficiency and reduces errors.

Essential Details

|

Showroom Location: Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, UAE Condition: New Type: Tile Forming Machine Tile Type: Steel Use: CEILING Production Capacity: 10-15m/min Place of Origin: China Brand Name: RELIANCE Voltage: 380V 50Hz 3phases or as your requirement |

Dimension(L*W*H): 5*1.0*1.3M Weight: 3500 kg Warranty: 1 Year Key Selling Points: Easy to Operate Rolling thinckness: 0.3-0.8mm Feeding width: Other Machinery Test Report: Provided Video outgoing-inspection: Provided Marketing Type: Ordinary Product Warranty of core components: 1 Year Core Components: Bearing, Gear, PLC After-sales Service Provided: Service Machinery Overseas |

Supply Ability

Supply Ability: 30 Set/Sets per Month

Packaging & delivery

Packaging Details: Containerized loading and fixing, plc with pollywood case pack.

Port: Xiamen Port, China

Lead time:

|

Quantity(sets) |

1 - 1 |

>1 |

|

Lead time (days) |

90 |

To be negotiated |

Product Display

Specification

|

Item |

Metal Stud Track Roll Forming Machine |

|

Applicable Industries |

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Restaurant, Home Use, Construction works , Other |

|

Showroom Location |

Saudi Arabia, Indonesia, Pakistan, India, Russia, Thailand, UAE |

|

Condition |

New |

|

Type |

Tile Forming Machine |

|

Tile Type |

Steel |

|

Use |

CEILING |

|

Production Capacity |

10-15m/min |

|

Place of Origin |

China |

|

Brand Name |

RELIANCE |

|

Voltage |

380V 50Hz 3phases or as your requirement |

|

Dimension(L*W*H) |

5*1.0*1.3M |

|

Weight |

3500kg |

|

Warranty |

1 Year |

|

Key Selling Points |

Easy to Operate |

|

Rolling thinckness |

0.3-0.8mm |

|

Feeding width |

Other |

|

Machinery Test Report |

Provided |

|

Video outgoing-inspection |

Provided |

|

Marketing Type |

Ordinary Product |

|

Warranty of core components |

1 Year |

|

Core Components |

Bearing, Gear, PLC |

|

After-sales Service Provided |

Service Machinery Overseas |

Packing & Delivery

Containerized loading and fixing, plc with pollywood case pack.

Company Profile

RELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification (issued by SGS).

FAQ

1. Who are we?

We are based in Fujian, China, start from 2018, sell to Southeast Asia(40.00%), South Asia(20.00%), Domestic Market(12.00%), Mid East(10.00%), North America(5.00%), Oceania(5.00%), South America(3.00%), Africa(2.00%), Eastern Asia(2.00%), Central America(1.00%). There are total about 5-10 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Roll forming machine, CZ purlin machine,metal roof sheet machine, slitting machine, cut to length machine.

4. Why should you buy from us not from other suppliers?

RELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, CNY;

Accepted Payment Type: T/T, L/C, Cash;

Language Spoken: English, Chinese

Why choose us?

- We offer a wide range of after-sales services to ensure the efficient use of Shutter Door System Machines.

- Our company is developing rapidly, steadily and healthily, speeding up the pace of international integration, pursuing excellent brand, abiding by the promise of service, and working together with you to create a better tomorrow.

- Our company offers flexible and efficient solutions for customers seeking Shutter Door System Machines.

- Establishing effective research and development risk prevention and research and development strength is the only way for our company to seize the market opportunity.

- We take pride in providing excellent customer service to ensure customer satisfaction.

- We have always believed and insisted on producing high-quality products based on high-precision, reliable, and well-maintained equipment.

- Our factory is equipped with cutting-edge technology and skilled workers to produce high-quality Shutter Door System Machines.

- For a long time, the company has established an excellent management team integrating design, production and marketing with the Metal Stud Track Roll Forming Machine industry as the pillar, market demand as the pillar, and marketing outlets all over the country. .

- Our company offers a warranty on all Shutter Door System Machines to ensure customer satisfaction.

- The company will continue to develop and update more technologies and products, uphold the business philosophy of "integrity, professionalism, and win-win", adhere to the principle of customer first, quality first, and better serve the development of the Metal Stud Track Roll Forming Machine industry .

Hot Tags: metal stud track roll forming machine, China metal stud track roll forming machine manufacturers, Equipment Grill Shutter Doors Rectangle Production, Stainless steel single layer door shutter machine, Octagon Pipe Shutter Door Roll Forming Machine, Shutter Door Forming Machines to India, Powerful Roll Up Door Forming Machine, Shutter door octagonal pipe roll forming machine

You Might Also Like

Send Inquiry