Automatic Heavy Duty Supermarket Shelf Panel Production Line For Sale

Brand Name: RELIANCE

Voltage: USER LOCAL STANDARD

Dimension(L*W*H): 42000*1800*1600mm

Weight: 40 ton

Warranty: 1 Year

Product Introduction

Essential Details

|

Applicable Industries: Building Material Shops, Manufacturing Plant, Home Use, Construction works , Other Showroom Location: None Condition: New Type: RACKING PANEL FORMING MACHINE Tile Type: GI, CR, HR STEEL Use: STORAGE SYSTEM Production Capacity: 2~3 Pieces per min Place of Origin: Fujian, China Brand Name: RELIANCE Voltage: USER LOCAL STANDARD Dimension(L*W*H): 42000*1800*1600mm Weight: 40 ton Warranty: 1 Year Key Selling Points: Automatic Rolling thinckness: 0.7mm |

Feeding width: basis on the size requried Machinery Test Report: Provided Video outgoing-inspection: Provided Marketing Type: Ordinary Product Warranty of core components: 1 Year Core Components: Motor, Bearing, Pump, PLC Product name: shelf panel Roll Forming Machine After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service Local Service Location: Viet Nam, Indonesia, India, Russia, Thailand, Malaysia, UAE After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support Certification: ISO9001 |

Supply Ability

Supply Ability: 30 Set/Sets per Month

Packaging & delivery

Packaging Details: Containerized loading and fixing, plc with pollywood case pack.

Port: Xiamen Port, China

Lead time:

|

Quantity(sets) |

1 - 1 |

>1 |

|

Lead time (days) |

120 |

To be negotiated |

Product Description

Specification

|

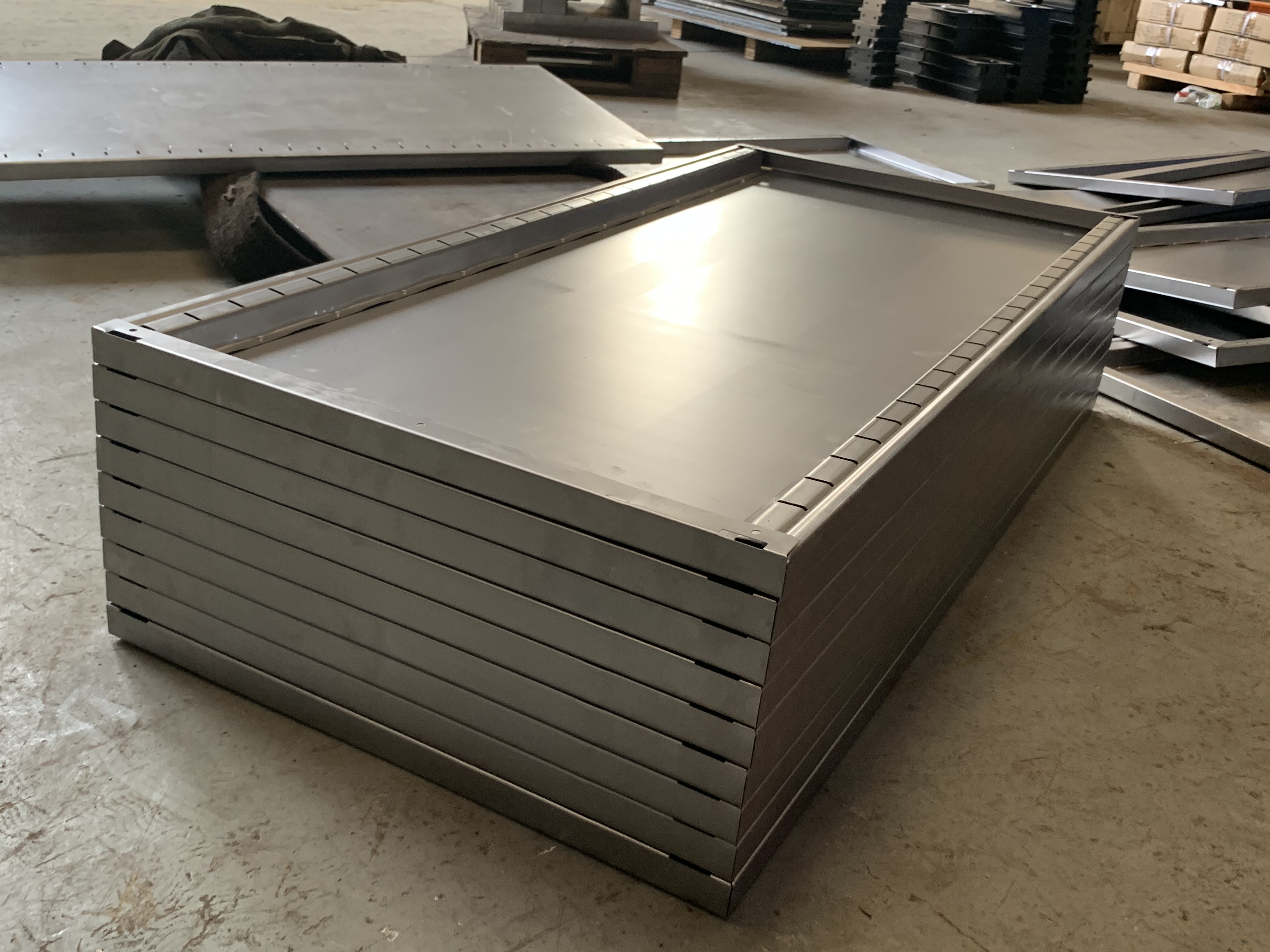

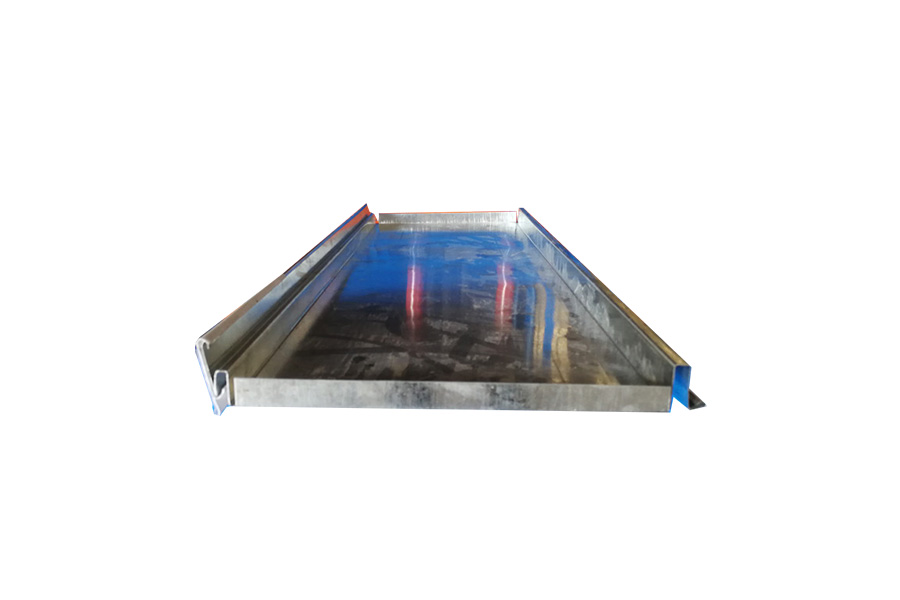

The 0.7mm thickness raw material for inspection, in common use |

The In-feed Section of the machine allows for variations in sheet width |

|

Totally two sets of hydraulic cylinders for notching&holes |

H Beam basis, All the wall plates with NC machining |

|

Main motor for roll forming: 11KW, Frequency speed control |

Stop to cut, Post cut, Slug breaker |

|

Powered conveyor table |

Hydraulic bending device |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Company Information

RELIANCE MACHINE (formally named as Xiamen Reliance M&N Machinery Industries Co., Ltd) was established in 2016, which covers an area of MORE THAN 10,000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, Meanwhile, we are the main drafter standard of China Non-standard roll former manufacturer and exporter of high quality roll forming machines in China. We are an ISO9001 approved company, and have European CE certification

We manufacture wide range products of metal sheet roll forming machines as follows: 1) for Metal Building Industry/PEB (Pre-Engineering Building): HAYES style quick change CZ purlin machine(including automatic and quick-change type C purlin machine and Z purlin machine), light gauge steel framing machine(LGSF, Howick and SCOTTSDALE style), roof panel forming machine, corrugated panel roll forming machine, curving machine, glazed tile roll forming machine, floor decking machine, ridge cap roll forming machine, cladding facade system forming machine, cut-to-length slitting line etc., as well as some hydraulic shearing machine, hydraulic folding machine for gutter and flashing, etc.

Exhibition

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1. Could I have prices of your products?

Welcome. Please feel free to send us an email here. You will get our reply in 24 hours

2. Can we print our logo/website/company name on products?

Yes

3. What's the lead time for regular order?

7-15 days for order quantity lower than 10pc

4. Can I get a discount?

Yes, please contact us to get the best price.

5. Do you inspect the finished products?

Yes, each step of production and finished products will be came out inspection by QC department before shipping.

Why choose us?

- Our Racking System Machines are manufactured to the highest quality standards.

- In terms of management work, we continuously improve the level of scientific and refined management, strengthen risk management and control, and ensure the realization of strategic goals.

- Our Racking System Machines are designed to maximize storage capacity and organizational efficiency.

- To create high-quality Automatic Heavy Duty Supermarket Shelf Panel Production Line For Sale is our consistent business philosophy!

- We are committed to providing sustainable and eco-friendly manufacturing practices.

- The investment in scientific research has also promoted the diversified innovation of our Automatic Heavy Duty Supermarket Shelf Panel Production Line For Sale.

- Our Racking System Machines are customizable to fit any workspace, making them perfect for any industry.

- We have a perfect after-sales service mechanism, and we always adhere to the spirit of service with a smile concept and sincere rational attitude to communicate with each customer.

- Our Racking System Machines are built with safety and reliability in mind.

- The core values are deeply rooted in our company, leading the enterprise to carry out all business activities without time limit.

Hot Tags: automatic heavy duty supermarket shelf panel production line for sale, China automatic heavy duty supermarket shelf panel production line for sale manufacturers

You Might Also Like

Send Inquiry